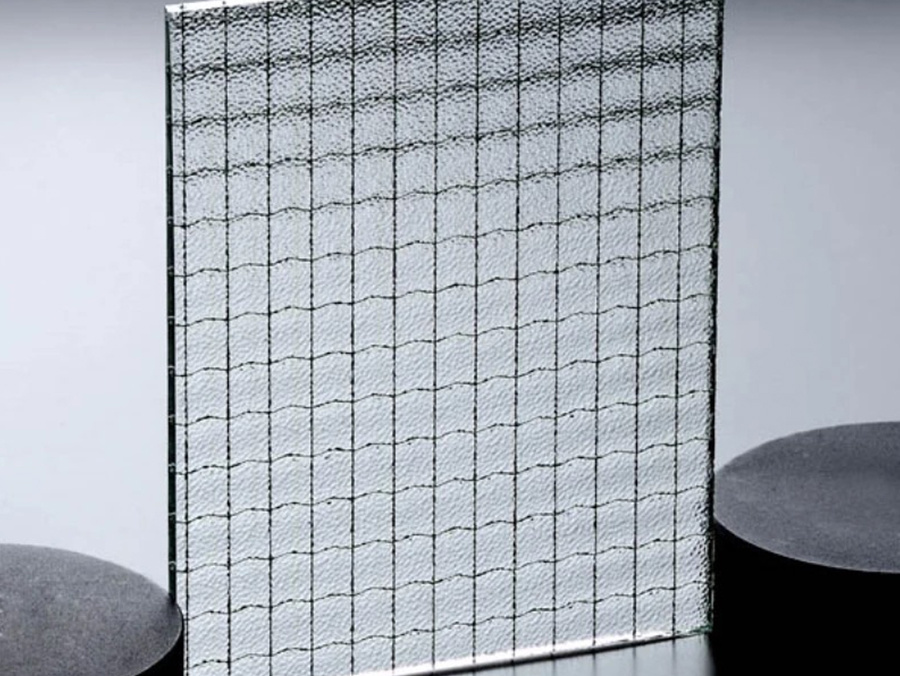

Tempered Glass

Product Features: High Flexural Strength, Impact Resistance, Resistant to Temperature Differences, Safety. Size Range: The size and thickness can be customized according to the customer's requirements. Applications: Curtain wall, Windows, Doors, Office Partitions, Guardrail, Lighting Roof, Appliances, Explosion-proof Facilities.

附件下载- Product Description

-

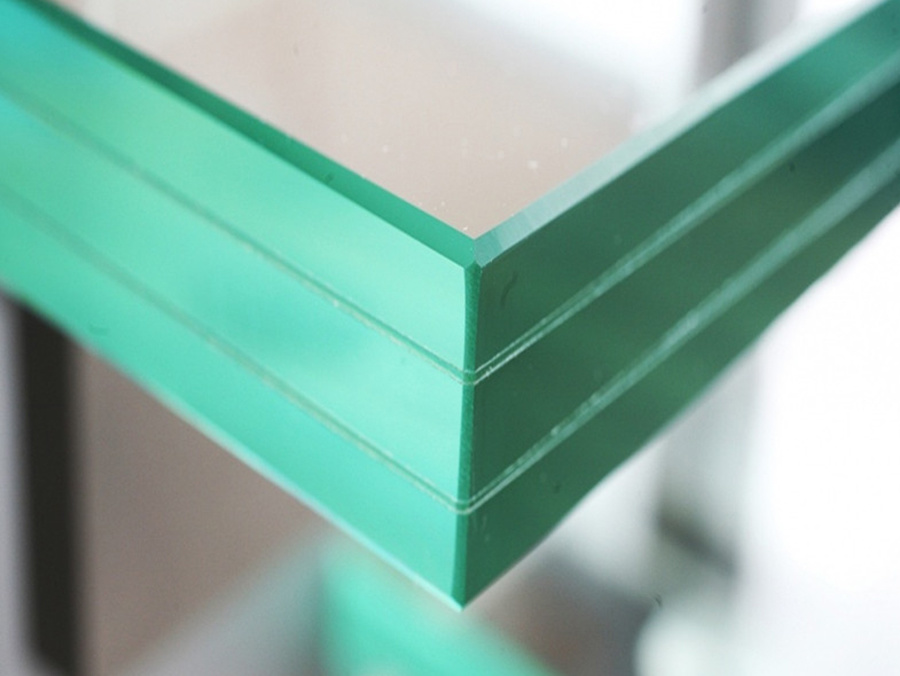

Tempered glass, semi-tempered glass is the ordinary glass heating and cooling treatment after the glass surface has a strong uniform compressive stress, mechanical strength exponentially increased glass. The surface compressive stress of tempered glass is above 90MPa, and the surface compressive stress of semi-tempered glass is between 24-52MPa.

Features

◆ Safety: glass broken into honeycomb like small obtuse particles, will not cause significant harm to the human body.

◆ High strength: the strength of tempered glass is 4 ~ 5 times that of ordinary glass.

◆ Deflection: 3 ~ 4 times larger than ordinary glass.

◆ Thermal stability: tempered glass has good thermal stability, can withstand the temperature is 3 times that of ordinary glass, can withstand the temperature difference of 300℃.

Semi-tempered glass features

Semi-tempered glass is also called thermal reinforced glass or reinforced glass, it and tempered glass surface compressive stress difference, its mechanical strength is 1.6 to 2 times of ordinary annealed glass, has good thermal stability. The degree of smoothness and transmittance of semi-tempered glass can be closer to ordinary annealed glass and is far better than tempered glass. Its big advantage is that there is no self-explosion.

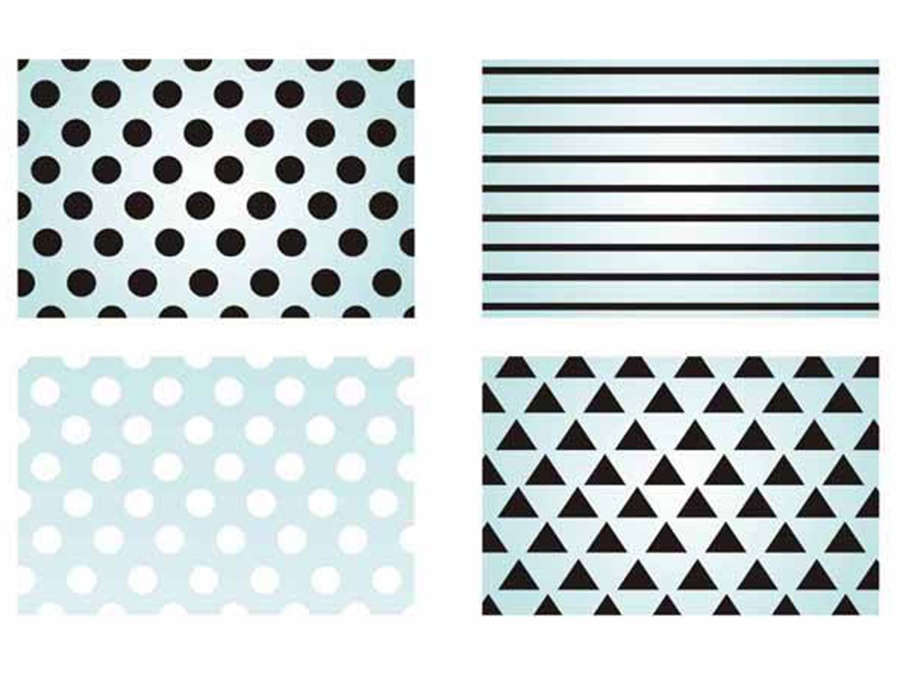

Applications

Widely used in places with high mechanical strength and safety requirements. Such as: glass doors, building curtain walls, facade Windows, indoor partition and close to the heat source and by hot and cold impact more intense position partition.

Specification

◆ Maximum size: 3300mm×15000mm

◆ Minimum size: 150mm×150mm

◆ Thickness range:Toughened glass: 3mm-19mm

Semi-tempered glass: 4mm-10mm

Quality standard

◆ Meet the national standard GB15763.2 "Building safety glass Part 2: Toughened glass"

◆ Meet the national standard GB17841-1999 "Toughened semi-toughened glass for curtain wall"

◆ Meet the Australian standard AS/NZ2208:1996

◆ Comply with ANSI Z97.1-2009 American standardMonolithic Float Glass

Glass Makeup

Visible Light(%)

Solar Energy(%)

U-value(W/m²K)

SC

SHGC 300nm-2500nm

SIR 780nm-2500nm

Trans

Reflect

Trans

Reflect

Winter

Summer

Outdoor

Indoor

3mm Clear

91

8

8

87

8

5.92

5.34

1.02

0.89

0.87

4mm Clear

90

8

8

85

8

5.88

5.31

1.01

0.88

0.85

5mm Clear

90

8

8

83

8

5.85

5.28

1.00

0.87

0.84

6mm Clear

90

8

8

82

8

5.82

5.25

0.99

0.86

0.83

8mm Clear

89

8

8

79

7

5.75

5.19

0.96

0.83

0.79

10mm Clear

88

8

8

76

7

5.68

5.14

0.94

0.82

0.76

12mm Clear

88

8

8

72

7

5.61

5.08

0.91

0.79

0.72

15mm Clear

88

8

8

70

7

5.52

5.00

0.90

0.78

0.71

19mm Clear

87

8

8

66

6

5.39

4.89

0.86

0.75

0.67

5mm F Green

77

7

7

48

6

5.85

5.28

0.72

0.62

0.50

6mm F Green

74

7

7

43

5

5.81

5.25

0.68

0.59

0.46

5mm Grey

50

6

6

51

6

5.85

5.28

0.74

0.65

0.64

6mm Grey

44

5

5

45

5

5.81

5.25

0.70

0.61

0.60

5mm K-Dark Blue

61

6

6

52

6

5.84

5.26

0.75

0.65

0.60

6mm K-Dark Blue

56

6

5

47

5

5.80

5.23

0.71

0.62

0.56

5mm K-Light Blue

77

7

7

59

6

5.84

5.26

0.80

0.70

0.61

6mm K-Light Blue

74

7

7

54

6

5.80

5.23

0.77

0.67

0.58

5mm Crystal Grey

67

6

7

61

6

5.85

5.28

0.82

0.71

0.68

6mm Crystal Grey

63

6

6

56

6

5.81

5.25

0.79

0.68

0.64

Low Iron Glass

Glass Makeup

Visible Light(%)

Solar Energy(%)

U-value(W/m²K)

SC

SHGC 300nm-2500nm

SIR 780nm-2500nm

Trans

Reflect

Trans

Reflect

Winter

Summer

Outdoor

Indoor

4mm Low Iron

91

9

9

89

8

5.88

5.31

1.04

0.90

0.90

5mm Low Iron

91

9

9

88

8

5.86

5.28

1.03

0.90

0.89

6mm Low Iron

90

9

9

88

8

5.82

5.25

1.03

0.90

0.89

8mm Low Iron

90

9

9

87

8

5.75

5.19

1.02

0.89

0.88

10mm Low Iron

90

9

9

86

8

5.68

5.13

1.01

0.88

0.86

12mm Low Iron

90

9

9

86

9

5.62

5.08

1.01

0.88

0.86

15mm Low Iron

89

9

9

83

8

5.53

5.01

0.99

0.86

0.83

19mm Low Iron

89

9

9

81

9

5.41

4.90

0.97

0.85

0.83

Message

上一页

下一页